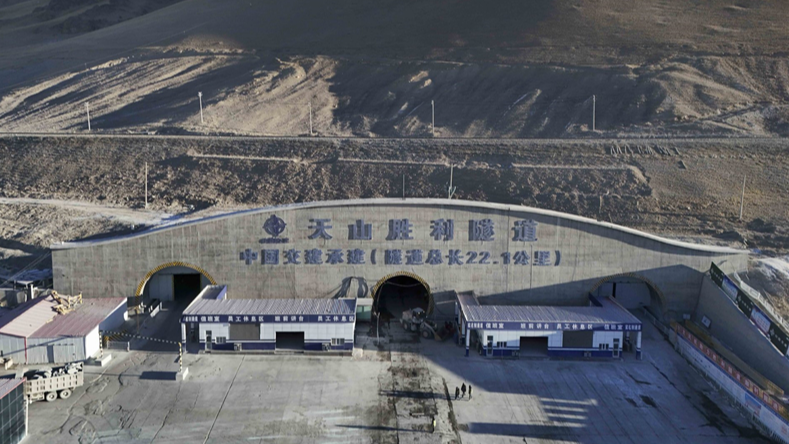

The Qianshan Shengli Tunnel, located in the Tianshan Mountains of the Xinjiang Autonomous Region in northwestern China, represents a remarkable engineering achievement due to the region’s challenging geological and climatic conditions.

Spanning 22.13 kilometers, the tunnel connects Urumqi with Korla in the Bayingolin region, reducing travel time across this mountainous area to approximately 20 minutes. The innovative construction techniques developed for this project are exceptional and are expected to serve as a benchmark for future large-scale projects in similarly demanding environments.

High-Altitude Construction Challenges

One of the project’s most significant challenges was the extreme altitude and harsh winter conditions. The tunnel is situated at elevations up to 3,000 meters, where winter temperatures can drop as low as -30°C. Constructing a durable underground roadway under these conditions required specialized materials and advanced construction methods to ensure both structural integrity and worker safety.To address these challenges, the project implemented advanced insulation technologies and systems to monitor and manage cold conditions. Materials resistant to extreme environments, including specialized mortars and thermally protective linings, were employed to guarantee durability.

Advanced Excavation and Support Systems

Given the tunnel’s length and the complex geology, innovative excavation and support solutions were essential. Advanced Tunnel Boring Machines (TBMs) were deployed to efficiently excavate the underground route. These machines can penetrate hard rock layers and, for the first time globally, were integrated with automated monitoring and control systems, enabling real-time adaptation to changing geological conditions.In addition, state-of-the-art tunnel wall reinforcement techniques were used, including carbon-fiber composite materials, to enhance structural strength and reduce long-term maintenance requirements.

Groundwater Management

Managing underground water posed another major challenge. Advanced monitoring systems, leveraging sensors and Big Data analytics, tracked moisture and groundwater flow in real time. This data was fed to control centers to predict and prevent flooding or other hazards.Complementary measures included reinforced barriers to prevent leaks and engineered drainage systems, ensuring the tunnel remains dry and safe for vehicular traffic.